Fundamental Components and Working Principles

A complete linear rail system comprises several key components that work together to achieve precise linear motion. The rail serves as the stationary guidance element, featuring precision-machined running surfaces that provide the pathway for moving components. The carriage or slider contains the mechanism that facilitates movement along the rail, typically incorporating recirculating ball or roller elements. Recirculating elements enable smooth, low-friction motion while supporting applied loads, with different configurations offering varying performance characteristics. Sealing systems protect internal components from contamination while retaining essential lubrication, and mounting accessories ensure proper installation and alignment. The system operates on the principle of constrained motion, where moving elements are guided along a precise path with minimal deviation, ensuring accurate and repeatable positioning throughout the operational range.

Types and Configurations

Linear rails are available in various configurations to meet specific application requirements. Profile rail systems feature rectangular rails with precision-ground raceways, offering high rigidity and load capacity in multiple directions. Round rail systems provide cost-effective solutions for applications with moderate precision requirements. Roller-based systems deliver higher load capacity than ball-based designs, making them suitable for heavy-duty industrial applications. Miniature linear rails address the need for precision motion in compact spaces, while motorized versions incorporate integrated drive systems for complete motion solutions. Each configuration offers distinct advantages in terms of precision, load capacity, stiffness, and cost-effectiveness, enabling engineers to select the optimal solution based on specific application needs.

Performance Characteristics and Technical Specifications

Understanding performance parameters is essential for proper linear rail selection and application. Load capacity encompasses static and dynamic ratings in radial, axial, and moment directions, determining the system's ability to withstand applied forces while maintaining performance. Precision specifications include running parallelism, positioning accuracy, and repeatability, typically measured in micrometers or microns. Stiffness characteristics define the system's resistance to deflection under load, critically affecting positioning accuracy and stability. Speed capabilities involve maximum velocity and acceleration ratings, while service life calculations consider applied loads, operating conditions, and maintenance practices. Environmental ratings specify protection levels against contamination and corrosion, following international standards such as IP classifications for dust and water resistance.

Material Technology and Manufacturing Excellence

The performance of linear rails heavily depends on advanced materials and precision manufacturing processes. Rails are typically manufactured from high-grade steel alloys with appropriate heat treatment for optimal wear resistance and durability. Stainless steel versions serve corrosive environments and cleanroom applications, while aluminum alloys provide lightweight solutions for high-speed applications. Rolling elements utilize precision-ground steel or ceramic materials, with ceramic options offering advantages in reduced weight, higher speed capability, and improved corrosion resistance. Advanced surface treatment processes including grinding, honing, and super-finishing create running surfaces with nanometer-level smoothness and geometrical accuracy. Rigorous quality control measures and automated inspection systems ensure every component meets exacting performance standards.

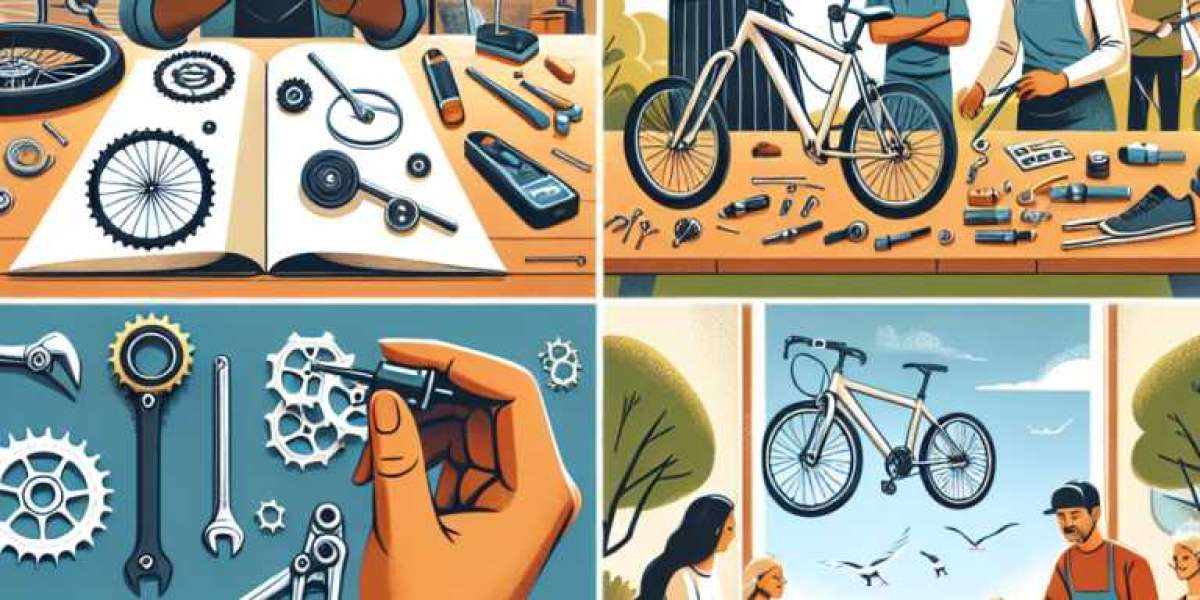

Installation Best Practices

Proper installation is crucial for achieving optimal linear rail performance and longevity. Foundation preparation requires specific flatness, straightness, and surface finish specifications to prevent inducing internal stresses or misalignment. Alignment procedures using precision instruments such as dial indicators, laser alignment systems, or optical levels ensure perfect parallelism and prevent binding. Mounting techniques must follow manufacturer specifications for bolt torque sequences and mounting surface preparation. Lubrication implementation from installation onward prevents early failure and maintains performance specifications. For critical applications, professional installation services may be necessary to ensure optimal results and prevent premature wear or failure.