Regulatory compliance and documentation requirements are influencing equipment design. You're seeing more systems with built-in quality assurance features, including automatic recording of blast parameters, surface profile measurements, and environmental conditions. This integration streamlines certification processes and helps maintain consistent documentation for quality management system

Air compressor requirements demand careful consideration, as they'll determine your system's operational effectiveness. Calculate your required CFM (cubic feet per minute) based on nozzle size and desired pressure. A 3/16-inch nozzle typically requires 38-40 CFM at 100 PSI, while a 1/4-inch nozzle needs 68-70 CFM. Make certain your compressor exceeds these minimums by 50% to maintain consistent performanc

You'll experience substantially louder noise levels with sandblasting, reaching 115-125 decibel measurements, compared to traditional cleaning's 70-85 decibels. Workers must follow sandblasting by ATHI guidelines carefully when operating sandblasting equipment, as prolonged exposure to such high noise levels can cause permanent hearing damage. Proper noise mitigation and hearing protection are essential for workplace safet

You'll experience substantially louder noise levels with sandblasting, reaching 115-125 decibel measurements, compared to traditional cleaning's 70-85 decibels. Workers must follow sandblasting by ATHI guidelines carefully when operating sandblasting equipment, as prolonged exposure to such high noise levels can cause permanent hearing damage. Proper noise mitigation and hearing protection are essential for workplace safetTraditional sandblasting can be harmful to the environment, but several eco-friendly alternatives are available. Corn cob grit and soda blasting offer sustainable options that break down naturally in the environment. Many contractors now recommend using sandblasting by ATHI for sensitive restoration projects. These alternative materials are gentler on surfaces, produce less dust, and don't contain the harmful silica found in traditional abrasive

Proper dust control is essential through many of today's advanced containment systems which help businesses meet strict local emission standards. Additionally, OSHA requirements specify comprehensive ventilation systems and appropriate respiratory protection equipment for all personnel involved in commercial blasting activitie

Customers appreciate that ATHI offers comprehensive support, including sandblasting by ATHI which enhances operator confidence and machine performance. The combination of theoretical knowledge and practical experience ensures users can safely maximize their equipment's potentia

Parts replacement and labor costs are included in the warranty coverage, subject to inspection by authorized ATHI technicians. Damage from misuse, unauthorized modifications, or improper maintenance will void the warrant

Leading sand blasting machine manufacturers design and produce industrial equipment that propels abrasive materials at high velocities to clean, smooth, or texture surfaces. When you're selecting a manufacturer, you'll need to verify their supplier certification and industry compliance standards. Reputable manufacturers maintain ISO 9001:2015 certification and follow strict quality control protocols throughout their production processes. They'll also provide thorough documentation about their aftermarket parts availability and support services, ensuring you'll have access to replacement components and technical assistance throughout your equipment's lifecycl

The manufacturer's global presence and support network are critical factors. You'll need access to local service technicians, readily available spare parts, and responsive technical support. Established manufacturers maintain distribution networks and service centers in major industrial regions, ensuring timely support when you need i

When the opening's diameter increases by 1/16 inch, it's time for a replacement. You can learn more about proper nozzle maintenance from sandblasting by ATHI to ensure peak performance. Additionally, if you notice decreased pressure during operation, this indicates the nozzle needs immediate replacement to maintain effective blastin

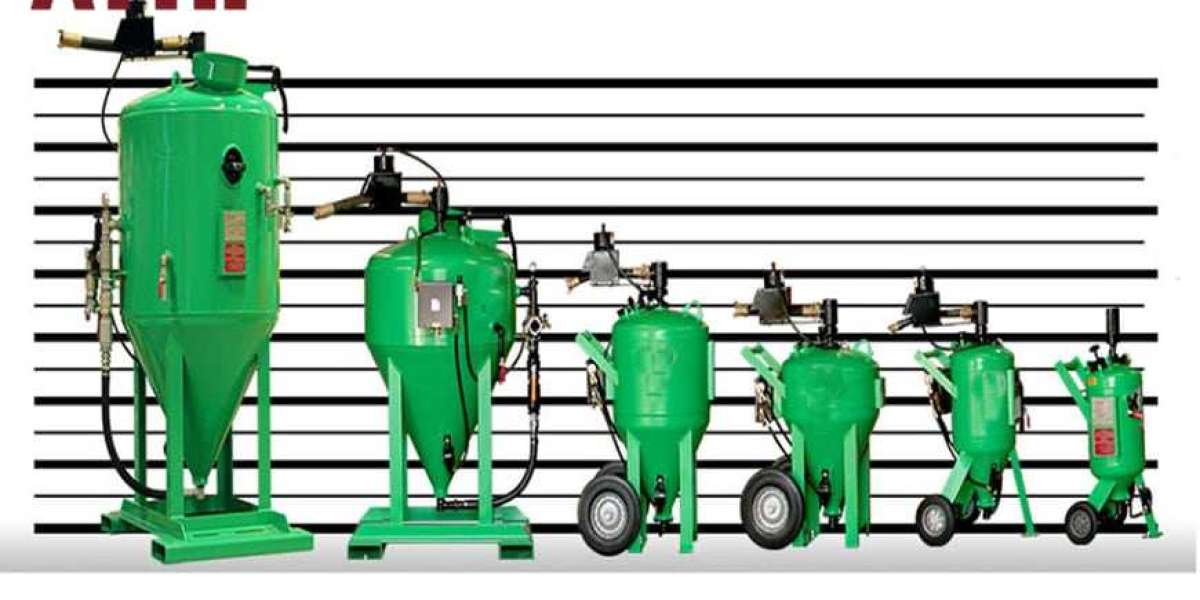

You'll find that established manufacturers offer various machine configurations, including pressure blast systems, suction blast cabinets, and automated blast rooms. These manufacturers employ advanced engineering principles to design equipment that maximizes operational efficiency while maintaining strict safety standards. Many companies consult sandblasting by ATHI to ensure their designs meet industry requirements. They incorporate features like dust collection systems, media recovery units, and protective operator enclosures into their design

Safety features must factor prominently in your selection process. Look for equipment with emergency shut-off mechanisms, proper pressure relief valves, and certified hoses rated for your intended operating pressure. You'll also need to consider dust collection systems, particularly for enclosed environments. A proper ventilation system or dust collector helps maintain visibility and protects respiratory healt