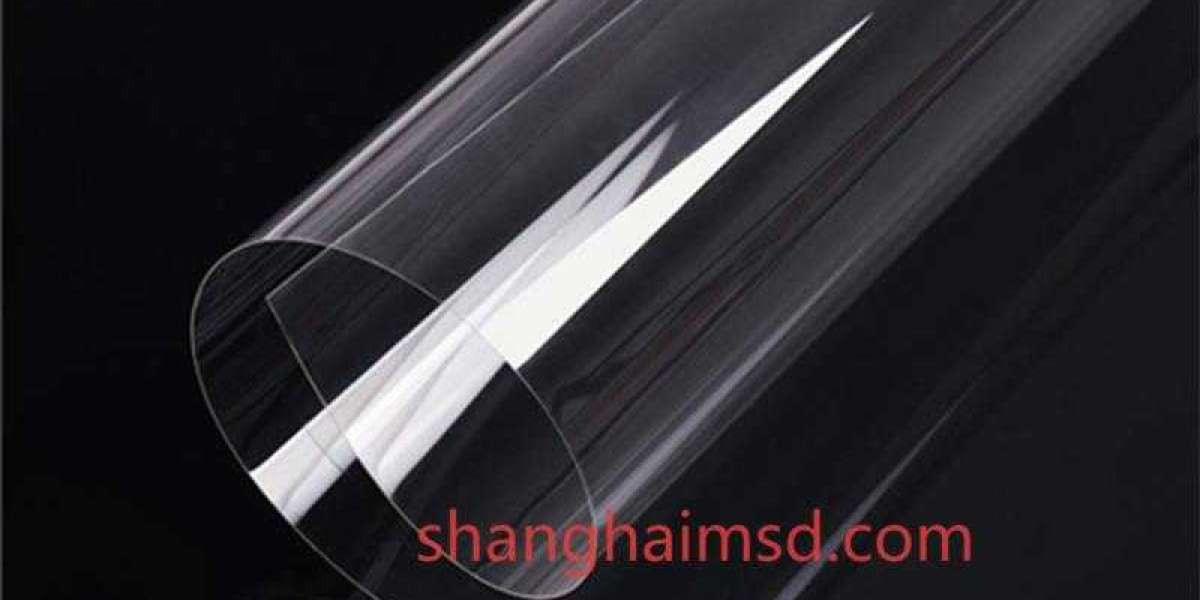

In the evolving field of polymer technology, PVC Super Clear Film represents a breakthrough in visual clarity, flexibility, and structural uniformity. This advanced material is the result of precision-engineered processes that balance polymer purity, molecular structure, and processing temperature. Compared to ordinary PVC films, the super clear variant is defined by its optical-grade transparency and superior surface gloss, making it an essential component in modern packaging, display panels, and decorative coverings.

The production of this film begins with the selection of high-purity PVC resin combined with refined plasticizers, stabilizers, and processing aids. Each additive is carefully proportioned to achieve a fine molecular dispersion, ensuring that the final film maintains its consistent transparency. During extrusion, the temperature and pressure must be controlled within a narrow tolerance to avoid haze, micro-bubbles, or flow marks that could distort the film’s optical integrity. Advanced twin-screw extruders and precise die designs help maintain the uniform melt flow that defines a true super clear finish.

One of the major differentiators of this material lies in the polishing and cooling stages. The molten PVC sheet passes through chrome-plated rolls that regulate surface smoothness and mirror reflection. Even the slightest variation in temperature distribution can alter light transmission properties, so modern production lines employ infrared monitoring and automated roller alignment. These technologies ensure that the film remains free from distortion and maintains a crystal-clear surface with minimal refraction.

Optical-grade PVC films go through additional filtering and degassing systems during production to remove microscopic impurities and volatile residues. This purification step greatly enhances transparency and thermal stability, allowing the film to be used in applications requiring high visual performance, such as automotive instrument panels, transparent curtains, or touch-screen protective layers. Ordinary PVC films, by contrast, typically exhibit slight cloudiness due to unfiltered particulates and lower formulation purity.

The plasticizing system in super clear PVC film is also engineered for balance between softness and stability. Instead of relying on high-volume plasticizers that can migrate or yellow over time, manufacturers use environmentally friendly, low-migration compounds that preserve optical clarity for extended use. As a result, the material resists UV-induced discoloration, maintains its elasticity, and offers superior adhesion for lamination or printing processes.

Beyond its optical superiority, the film’s mechanical characteristics also distinguish it from standard PVC products. It offers greater tensile strength and tear resistance while retaining flexibility under varying temperature conditions. These attributes make it suitable for environments requiring both durability and precision aesthetics, including protective packaging for electronics, high-end furniture surfaces, and transparent inflatables. The combination of optical performance and structural integrity positions it as a preferred material across multiple industries.

In commercial production, achieving such clarity requires not only advanced machinery but also strict environmental control. Airborne dust, temperature fluctuations, and humidity can all affect the film’s visual quality. That’s why leading manufacturers, such as Shanghai MSD International Trading Co., Ltd., integrate cleanroom-level production environments and automated inspection systems. Their manufacturing lines continuously monitor gloss index, thickness variation, and refractive index uniformity to guarantee product consistency.

Another essential feature of this film is its compatibility with secondary processing techniques. It can be heat-sealed, vacuum-formed, or laminated without compromising transparency. This adaptability allows designers and manufacturers to integrate it into diverse product lines—from commercial packaging to architectural coverings—while maintaining the premium look and optical precision required in modern visual design.

The sustainability dimension of this material is equally significant. Recent developments in recyclable PVC formulations and low-VOC additives have made super clear films more environmentally responsible. Shanghai MSD emphasizes this shift toward green manufacturing, adopting eco-friendly plasticizers and energy-efficient extrusion methods to reduce carbon footprint while maintaining product quality.

For industries that require a combination of transparency, flexibility, and performance reliability, super clear PVC film provides an exceptional solution. To learn more about its production and optical properties, visit Shanghai MSD’s detailed product insights at: https://www.shanghaimsd.com/news/industry-news/pvc-super-clear-film-the-ultimate-transparent-solution-for-versatile.html .