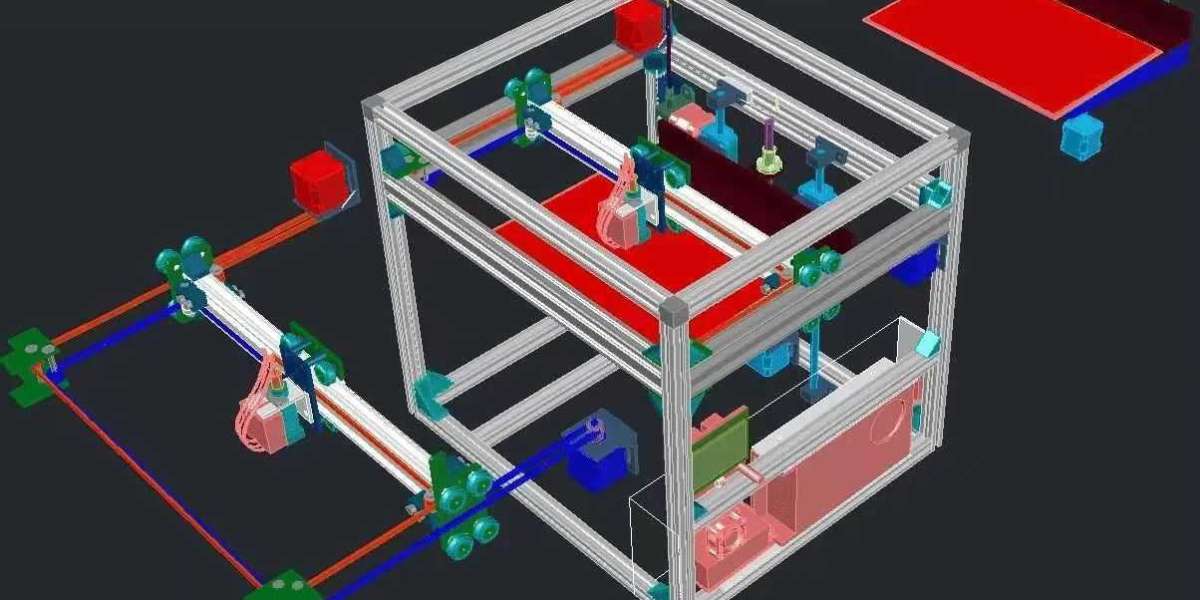

The working principle of the Core XY printer is based on the joint operation of two motors.

On both sides of the printing platform, a motor is installed respectively, and the two motors are connected to the slide frame through a synchronous belt. When the two motors rotate in the same direction, the slide frame moves in the X-axis direction; When the two motors rotate in reverse, the slide frame moves in the Y-axis direction. This design not only improves the stability of the motion, but also reduces the errors that can occur when a single motor controls an axis, thus ensuring the accuracy of the printing process.

The design principle of the combination of two motors is a major improvement on the traditional Cartesian motion.

In traditional 3D printers, three independent motors are usually used to control the motion in X, Y, and Z directions respectively. However, this design is prone to jitter and loss of accuracy when printing at high speeds. The Core XY printer effectively solves this problem through the synergy of dual motors, making the printing process smoother and more precise, so that it can meet the production needs of higher standards.

Another highlight of the Core XY printer is its unique two-layer conveyor belt design.

The two belts appear to intersect on the same plane, but are actually located at different levels, thus avoiding interference during movement. This design not only optimizes the spatial layout, but also further enhances the stability of the printer, ensuring that it remains efficient and reliable during long periods of operation.

The Core XY printer is equipped with a high-precision stepper motor on the slide frame moving in the X and Y directions.

These motors achieve tiny movements of the slide frame by precisely controlling the pulse signal, thus ensuring the precise positioning of the print head. The use of stepper motors allows the Core XY printer to maintain a high degree of printing accuracy when dealing with complex models, meeting the needs of various precision manufacturing.

The combined dual-motor design of the Core XY printer not only improves printing speed and accuracy, but also opens up new possibilities for 3D printing technology. With the continuous progress of technology, Core XY printers will be widely used in more fields, injecting new vitality into the intelligent development of manufacturing. Whether it is in medical, automotive, aerospace or consumer electronics, Core XY printers can leverage their unique advantages to push related industries to the next level of development.

In short, the Core XY printer achieves efficient and stable printing results through the joint operation of dual motors. Its exquisite design and excellent performance make it an indispensable and important tool in the modern manufacturing field. In the future, Core XY printers will continue to lead the development trend of 3D printing technology, bringing more innovation and breakthroughs to all walks of life. With the continuous innovation and application expansion of technology, Core XY printers will undoubtedly occupy a more important position in the global manufacturing industry.