Unlock the Future: Discover the Game-Changing Benefits of High-Capacity 3D Printers!

3D printing has revolutionized the way we conceptualize and create objects, evolving from a niche technology into a fundamental part of modern manufacturing and design. Once limited to prototyping, 3D printing now encompasses a vast array of applications, from fashion to automotive parts, and even medical implants. However, one of the most crucial aspects of this technology is its capacity. The ability to produce large-scale objects can significantly impact productivity and efficiency across various industries. In this article, we will delve into the world of professional 3D printers with big capacity, exploring their specifications, features, and the numerous benefits they offer to businesses and creators alike.

Understanding High-Capacity 3D Printers

A high-capacity 3D printer is defined by its ability to produce larger objects than standard models, often featuring a build volume that exceeds several cubic feet. These printers are equipped with advanced technologies that allow them to handle a variety of materials, including thermoplastics, resins, and even metal composites. What sets high-capacity printers apart is their intricate engineering, which supports not only larger prints but also the ability to print multiple items simultaneously, thus boosting overall efficiency. This capability is especially beneficial for industries that require rapid prototyping or large production runs, allowing for quicker turnaround times and enhanced workflow.

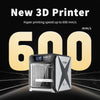

Key Features of Professional 3D Printers with Big Capacity

When considering a professional 3D printer with big capacity, several key specifications come into play. Build volume is paramount, as it determines the maximum size of the end product. Speed is another critical feature, with many advanced models capable of producing high-quality prints at a rapid pace. Precision is equally important; high-capacity printers often boast advanced technologies such as Fused Deposition Modeling (FDM) or Stereolithography (SLA), which enhance the accuracy of prints. Additionally, features like multi-material printing capabilities allow for greater versatility in design, enabling users to create complex parts with different properties in a single print job. These specifications not only enhance the performance of the printer but also contribute significantly to cost efficiency in large-scale production.

Benefits of Using High-Capacity 3D Printers

The advantages of utilizing professional 3D printers with large capacities are manifold. First and foremost, these printers can significantly increase productivity by reducing the time required for production. This is particularly advantageous for businesses that rely on rapid prototyping and need to iterate designs quickly. Moreover, high-capacity printers are cost-effective for large production runs, as they streamline the manufacturing process and minimize material waste. The versatility of these machines allows for applications across multiple industries, from creating intricate prototypes in the automotive sector to producing custom medical devices in healthcare. By leveraging the capabilities of high-capacity 3D printers, companies can enhance their operational efficiency and gain a competitive edge in their respective fields.

Applications Across Industries

High-capacity 3D printers are making waves across a variety of sectors, each reaping the benefits of this innovative technology. In the automotive industry, for instance, manufacturers are using large-scale 3D printers to produce lightweight components that enhance fuel efficiency. The aerospace sector benefits similarly, utilizing these printers to create complex parts that meet stringent safety standards while reducing weight. In healthcare, 3D printing allows for the customization of prosthetics and surgical tools, tailored specifically to individual patients, which can improve outcomes significantly. Architecture also leverages high-capacity printing for creating detailed models and even entire structures, showcasing the versatility of this technology. With such diverse applications, it's clear that high-capacity 3D printers are becoming indispensable tools across various industries.

Future Trends in 3D Printing Technology

The field of 3D printing is rapidly evolving, with numerous trends and innovations shaping the landscape of high-capacity machines. One notable trend is the integration of artificial intelligence and machine learning to optimize printing processes, allowing for smarter, more efficient production methods. Additionally, advancements in material science are enabling the use of new, high-performance materials that enhance the strength and durability of printed objects. As sustainability becomes a focal point in manufacturing, we can also expect to see more eco-friendly materials being developed for use in 3D printing. Furthermore, the rise of on-demand manufacturing is likely to redefine supply chains, with high-capacity 3D printers enabling companies to produce parts locally, reducing lead times and transportation costs. These trends herald a future where 3D printing continues to disrupt traditional manufacturing paradigms.

Transforming Industries with High-Capacity 3D Printing

In summary, high-capacity 3D printers are not just a passing trend; they represent a significant shift in the way products are designed and manufactured. With their impressive specifications and numerous advantages, these machines are transforming industries by enhancing productivity, reducing costs, and enabling greater design flexibility. As we look to the future, it’s essential for businesses and creators to consider how embracing high-capacity 3D printing technology can revolutionize their operations and drive innovation in their fields. The possibilities are vast, and the time to explore them is now.