In today's world, the demand for efficient cooling technology is critical across a wide range of industries. From high-performance computing systems to electric vehicle batteries, cooling components like cold plates are essential for managing heat and ensuring the longevity and effectiveness of equipment. Cold plate manufacturers play a crucial role in producing these specialized cooling solutions that are tailored to various industrial needs.

What Are Cold Plates?

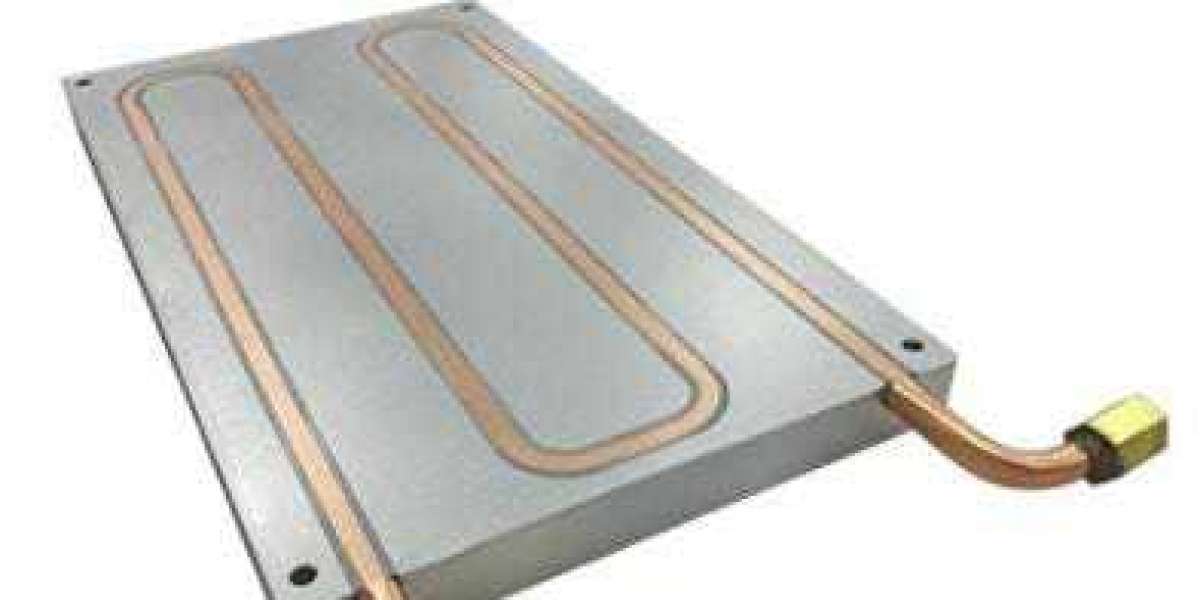

Cold plates are metal devices designed to absorb and transfer heat away from high-temperature components through a cooling medium, typically a liquid or refrigerant. They are widely used in applications where air cooling alone is insufficient to manage heat loads. By conducting heat away efficiently, cold plates prevent overheating, which can lead to system malfunctions or damage. Industries that rely heavily on these components include electronics, telecommunications, automotive, and aerospace sectors, where efficient thermal management is vital.

Manufacturing Process of Cold Plates

Cold plate manufacturers employ advanced processes to create plates that meet specific cooling requirements. These processes often involve intricate designs that optimize heat transfer and fluid flow within the cold plate. Manufacturing techniques vary, but some common methods include brazing, which joins metals at high temperatures; and friction stir welding, which provides strong, durable bonds. Cold plate manufacturers also use computer-aided design (CAD) and thermal simulations to ensure that each plate meets the precise specifications for optimal thermal performance.

Applications of Cold Plates Across Industries

Electronics and Computing: Cold plates are widely used in high-performance computing systems, such as data centers and GPUs, to manage the significant heat generated by continuous processing tasks.

Automotive Industry: Electric vehicles (EVs) rely on cold plates to cool battery packs, ensuring they operate within safe temperature limits. This cooling extends battery life and improves vehicle performance.

Aerospace and Defense: High-powered radar systems, lasers, and avionics require efficient cooling solutions to maintain functionality under intense conditions. Cold plate manufacturers often produce custom plates for these specialized applications.

Medical Devices: Some advanced medical equipment, like MRI machines and CT scanners, requires precise cooling to function accurately. Cold plate manufacturers provide solutions that keep these devices stable and safe.

Choosing the Right Cold Plate Manufacturer

Selecting a reliable cold plate manufacturer is essential for businesses that need customized cooling solutions. Factors to consider include the manufacturer’s expertise, quality control measures, and their ability to meet specific thermal requirements. Many top manufacturers offer customization services, allowing businesses to order cold plates designed precisely for their applications, ensuring efficiency and reliability in operation.

Future of Cold Plate Technology

As technology continues to advance, the need for efficient thermal management solutions will only increase. Cold plate manufacturers are responding by researching new materials, optimizing designs for improved heat transfer, and developing more compact and lightweight plates suitable for emerging applications. Future developments may include the integration of smart sensors and monitoring systems within cold plates to provide real-time temperature tracking, which can be invaluable for industries where precise control over cooling is essential.

In conclusion, cold plate manufacturers are fundamental to modern thermal management solutions. Their expertise and innovation enable industries to operate efficiently, safely, and sustainably, making them indispensable in today’s technology-driven landscape.